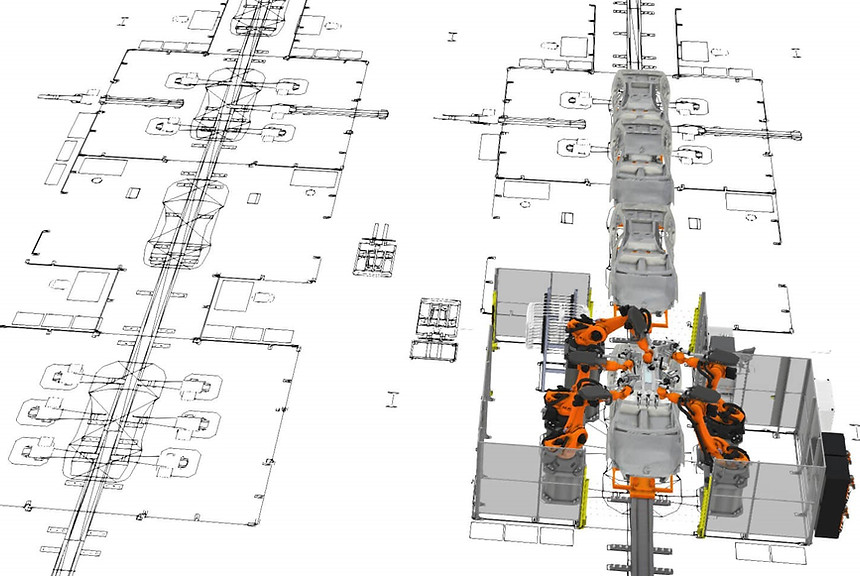

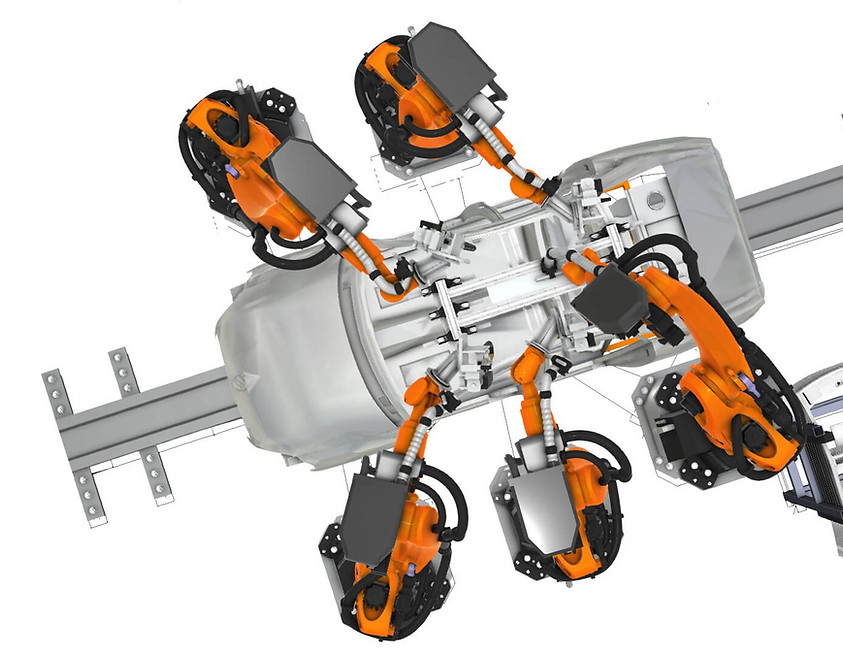

The next generation of 3D manufacturing simulation technology. Designed for manufacturing professionals and built on a powerful, flexible, and scalable platform.

Find the right product for your application

Whether you’re looking for a tool to quickly design and present production solutions, or a platform to power your offline programming applications, we’ve got you covered.

SMARTER SIMULATIONThe Visual Components platform was designed to support advanced 3D manufacturing simulation applications. The physics behavior, powered by the NVIDIA PhysX engine, allows you to simulate and visualize functionality affected by physical forces, such as collisions, gravity, and material properties. |

.jpg) |

|

BETTER PERFORMANCEVisual Components was developed to take full advantage of the 64-bit Windows environment. This means better graphics, faster loading times, and a much smoother user experience. Navigating large layouts is fluid. Memory management is constantly being optimized to improve simulation performance. The CAD converter has been optimized to import geometries into the Visual Components 3D world quickly. |

ADVANCED RENDERINGVisual Components includes several rendering modes, helping you see more details and features and providing a richer and more immersive viewing experience. With advanced lighting and shading models and the ability to view material textures, models in the 3D world look realistic and pictures and videos exported from the platform are marketing-grade. The x-ray mode helps with identifying root causes and issues when you’re designing new components, configuring layouts, and analyzing collisions. |

|

"Visual Components is so versatile that it was very easy to implement the different configurations and view their effect on the cycle time. Once we found the best simulation, we were able to edit a video of the process and provide quantified and visual reasoning to support our final solution."

Corentin Monnot, Project Manager at FiRAC

Check out our family of 3D manufacturing simulation products.

ESSENTIALSDesign, build and simulate your factory of the future using ready-made components. KEY FEATURES

|

PROFESSIONALDefine and create your own components to simulate in our 3D world. KEY FEATURES

|

PREMIUMVirtualize your factory with our complete manufacturing simulation solution KEY FEATURES

|

PR Automation Ltd manufacture a wide range of control panels for several markets and environments.

PR Automation Ltd have an experienced team of control engineers to provide customer focussed bespoke controls solutions to meet demanding standards, timing and budget.

PR Automation Ltd boast an in-house team of software engineers who are skilled in many PLC languages.

PR Automation Ltd provide a virtual engineering service to include simulation, emulation and virtual validation for in-house or external clients projects.

PR Automation Ltd believe that successful projects are firmly routed in the management system employed to deliver a predictable and repeatable project outcome.

PR Automation Ltd install a diverse range of power & control systems to the highest standards

PRA’s new I/O validating app enables networked I/O to be confirmed against the design by the installation electrician without the need for PLC code experience.

SHEco Engineering was incorporated in 1983 and forms part of the Quality Group